Mould fluxes have a significant effect on the efficiency of the continuous casting process and the surface quality of the steel product is strongly affected by them.

Mould

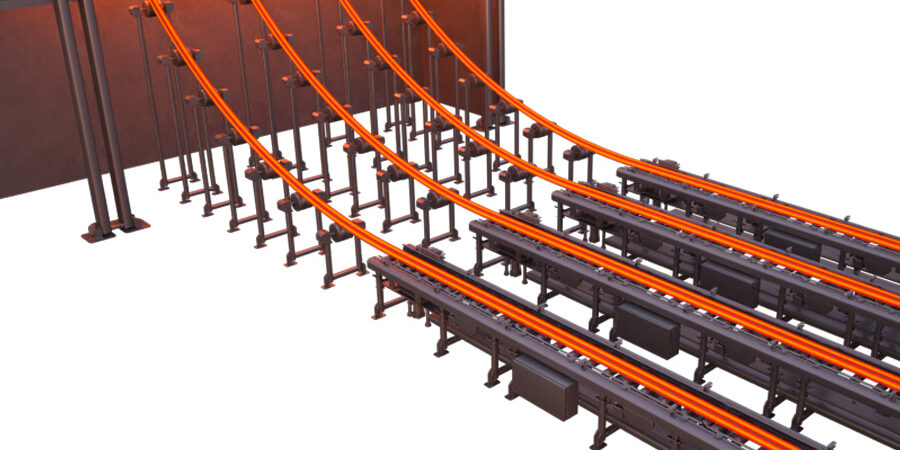

Continuous casting solutions

- Main properties

- Lubrication between the steel shell and mould wall

- Thermal insulation of the liquid steel surface

- Liquid steel re-oxidation prevention

- Control of the heat transfer between the strand and the mould

- Equal flux distribution over the melted steel

- Inclusions entrapment

- Enhancing of steel product surfaces

Ingot casting solutions

Bottom pouring powders

- Main properties

- Thermal insulation of the liquid steel surface

- Liquid steel re-oxidation prevention

- Inclusions entrapment